PRODUCTS

PRODUCTS

MESSAGE

pipe fitting elbow, 90 degreeelbow, pipe elbow, elbow fitting

Delivery time:Usually 3-7 days, or upon negotiation

Competitive price and quality from our own factory

Terms of price: EXW, FOB, CFR, CIF

Payment Term:TT,L/C,etc

Certificates: SGS, MTC, ISO9001, CE, SGS

If you have any questions, please feel free to contact us.

PRODUCT INTRODUCTION

What is a Piping Bend?

A pipe bend is the generic term for what is called in piping as an “offset” – a change in direction of the piping. A bend is usually meant to mean nothing more than that there is a “bend” – a change in direction of the piping (usually for some specific reason) – but it lacks specific, engineering definition as to direction and degree. Bends are usually custom-made (using a bending machine) on site and suited for a specific need. Bends are usually made by using a bending machine (hot bending and cold bending) on-site and suited for a specific need. The use of bends is economic as it reduces the number of expensive fittings.

What is a Piping Elbow?

A PIPING ELBOW, on the other hand, is a specific, standard, engineered bend pre-fabricated as a spool piece (based on ASME B 16.9) and designed to either be screwed, flanged, or welded to the piping it is associated with. An elbow can be 45 degrees or 90 degrees. There can also be custom-designed elbows, although most are categorized as either “short radius” or long radius”.

Pipe bends typically have a minimum bending radius of 1.5 times pipe radius (R). If this bending radius is less than 1.5R, it is called Elbow. Reference to any international / industry standard need to be traced. 1.5, 3 and 4.5 R are the most common bending radii in industry.

A pipe bend typically flows smoother since there are not irregular surfaces on the inside of the pipe, nor does the fluid have to change direction abruptly.

The most basic difference of them is the elbow relatively short than bend, R = 1D to 2 D is elbow More than 2D is bend. In the production process, cold bends can use Bending Machine to bend by ready-made straight bend. One-time completed also don’t need second corrosion. But elbow need manufacturers make to order, to do anti-corrosion, order cycle is long. Elbow price is higher than bend. But cost performance is much higher than bend. It is well-known that bend do not have anticorrosive processing is easy damaged, but the price is cheap so are used very much in some demand which not very high engineering.

Elbow and Bend Description

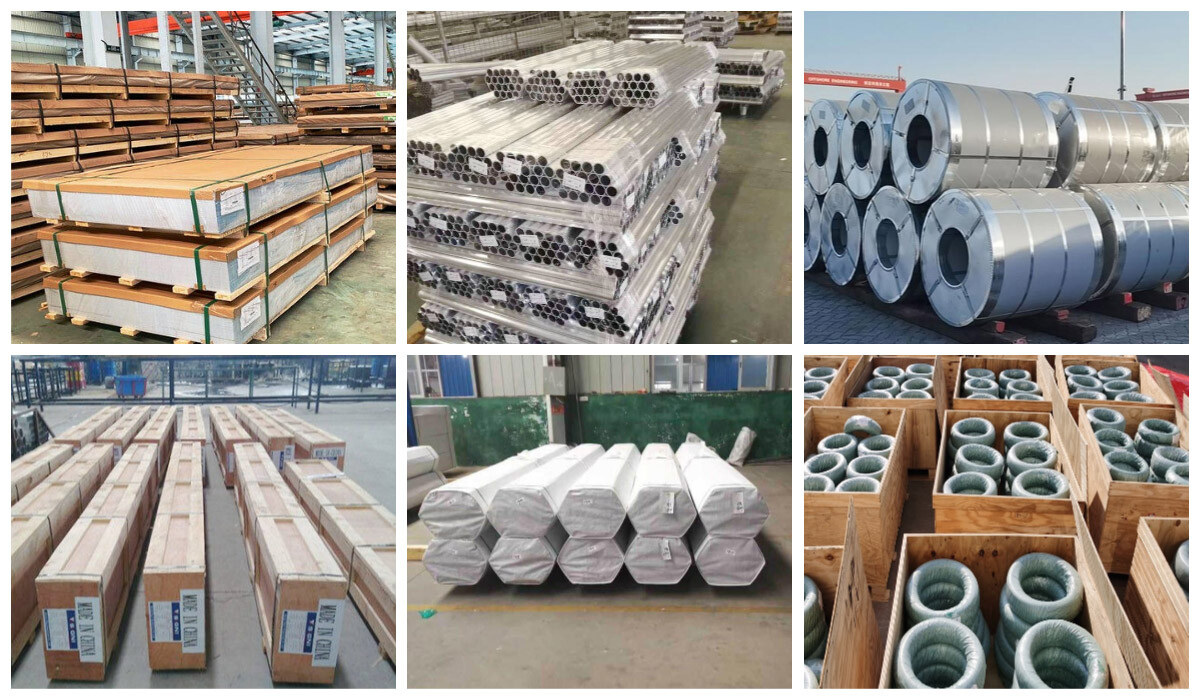

PACKAGING

WHY CHOOSE US

Wuxi Dingyu Xinda Special Steel

Wuxi Dingyu Xinda Special Steel Co., Ltd. is a large sales base for spot supply and production of stainless steel pipes and special materials in China. It mainly deals in various imported and domestic stainless steels, pipes, plates, bars, profiles, pipe fittings and welding materials. The company has a strict and effective quality management system, complies with IS09001: 2008 standard certification, and provides supporting materials for petroleum, chemical, electric power, and shipbuilding industries.

All products of the company comply with the national standard (GB), American standard (ASME, ASTM), Japanese standard (JIS) EN (European standard) GOST (Russian standard), our company holds the ISO9001-2008 quality system certificate issued by TUV Rheinland, Germany and the EU PED/97/23/EC certificate for pressure equipment, API 6A and API 17D certificates issued by API of American Petroleum Institute, and certification of classification societies of eight countries.

LEAVE A MESSAGE

RECOMMENDED PRODUCTS

Please give us a message