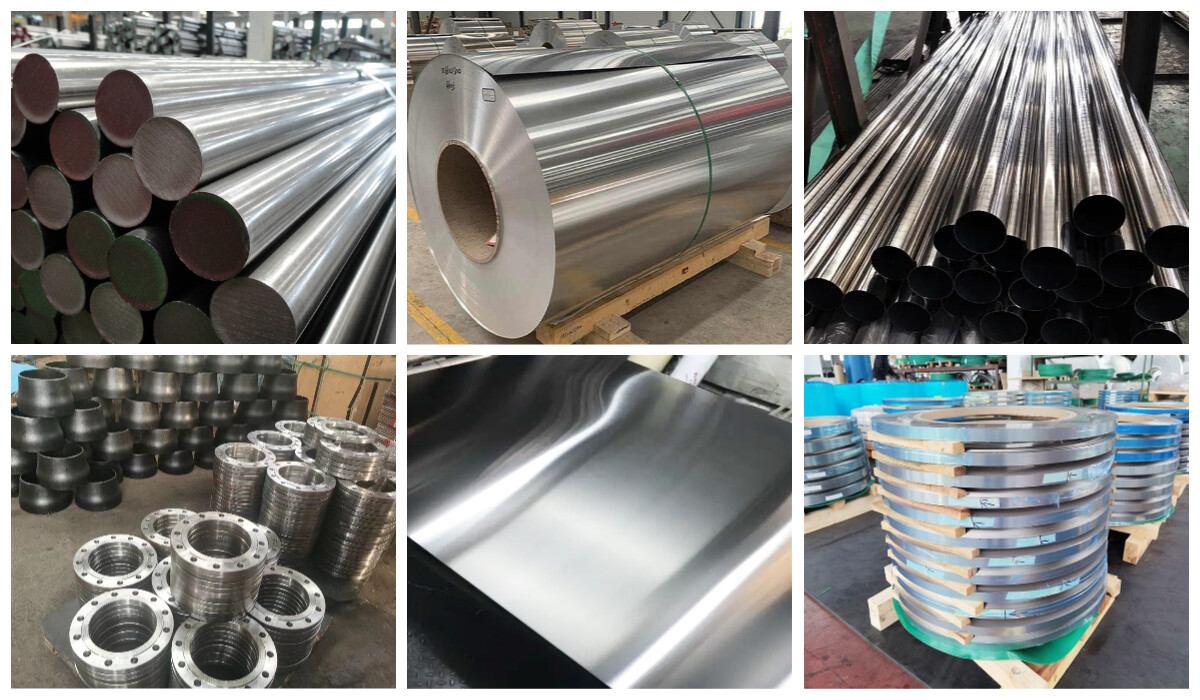

PRODUCTS

PRODUCTS

MESSAGE

Nickel-Molybdenum Alloys,Nickel-Chromium-Iron Alloys

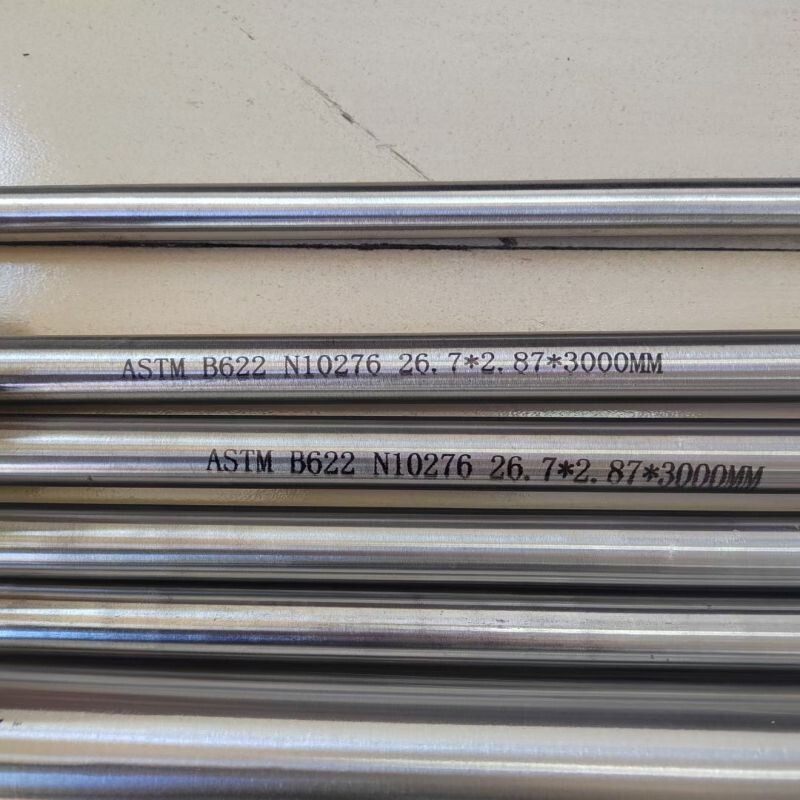

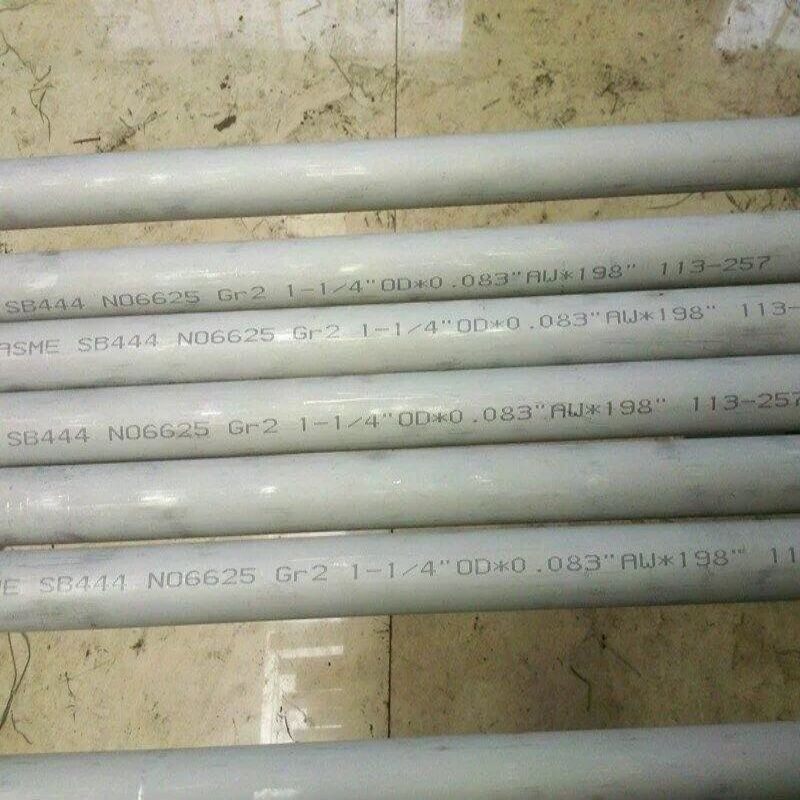

Available Standard: ASTMA162,GB/T2054,DIN177502002,ASTM B127,ASTM B435,ASTMB582,

ASTM B575, ASTM B168,ASTM B443, ASTM B463,ASTM B626,ASTM B536,etc

Material: : NO2200,NO2201,NO4400,NO4404,NO4405,NO5500,NO6002,NO6007,

NO6022,NO6025,NO6030,NO6045,NO6059,NO6102,NO6200,NO6230,NO60333,

MO60455,NO6600,NO7001,NO7750,NO8221,NO8020,NO8024,NO8800,etc.

Delivery time:Usually 3-7 days, or upon negotiation

Terms of price: EXW, FOB, CFR, CIF

Payment Term:TT,L/C,etc

If you have any questions, please feel free to contact us.

PRODUCT INTRODUCTION

Nickel will alloy readily with many other metals, including chromium, iron, molybdenum and copper. This allows for a wide variety of alloys that demonstrate outstanding resistance to corrosion and high-temperature scaling, exceptional high-temperature strength and other unique properties, such as shape memory and low coefficient of expansion.

The following is a simplistic categorisation of the various nickel alloy types.

Wrought Nickel

Pure nickel UNS N02200 is used in the chemical industry for its corrosion resistance - particularly to alkalis. It is also used for its properties in shielding against electromagnetic interference and in transducers.

Nickel-Iron Alloys

These are used as soft magnetic materials, as glass-to-metal seals and as materials with defined thermal expansion properties.

Invar® (UNS K93600), with 36% nickel and the remainder iron, is unique in having an almost zero coefficient of thermal expansion around room temperature. This makes it valuable where high dimensional stability is required, such as in precision measuring instruments and thermostat rods. It is also used at cryogenic temperatures because of its very low thermal expansion rates.

Alloys containing 72-83% nickel have the best soft magnetic properties and are used in transformers, inductors, magnetic amplifiers, magnetic shields and memory storage devices.

Nickel-Copper Alloys

These are highly resistant to corrosion by alkaline solutions, non-oxidizing salts and seawater. The best-known is Alloy 400.

Nickel-Molybdenum Alloys

These are highly resistant to reducing acids in the absence of oxidizing ions, such as ferric and cupric or dissolved oxygen. The best-known is Alloy B-2.

Nickel-Chromium Alloys

These are characterised by their high resistance to corrosion at both normal and high temperatures (resistance to scaling), good high-temperature strength and high electrical resistance. There are three main groups of alloys:

·Ni-Cr (and also Ni-Cr-Fe) alloys with high electrical resistance for heating elements, such as 70-30 (UNS N06008) and C-Grade (UNS N06004)

·Ni-Cr alloys (with Fe and other alloying elements) with good corrosion resistance. The best-known are Alloy 600 (UNS N06600) and Alloy 601 (UNS N06601)

·Ni-Cr alloys with high-temperature strength and creep resistance, mostly age-hardenable, such as Alloy X-750 (UNS N07750)

Nominal composition of various nickel alloys:

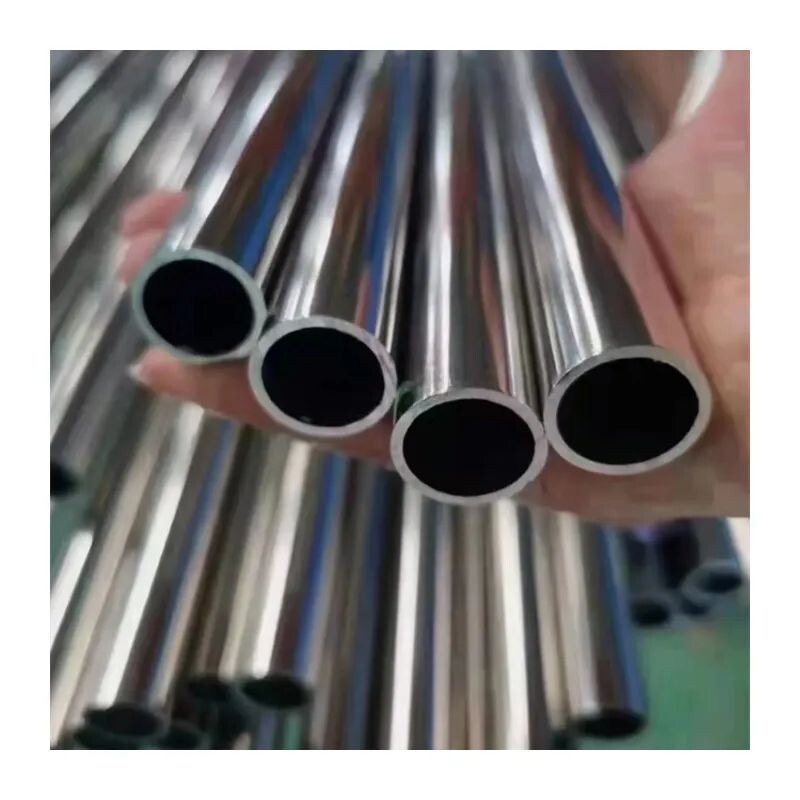

Product Parameters:

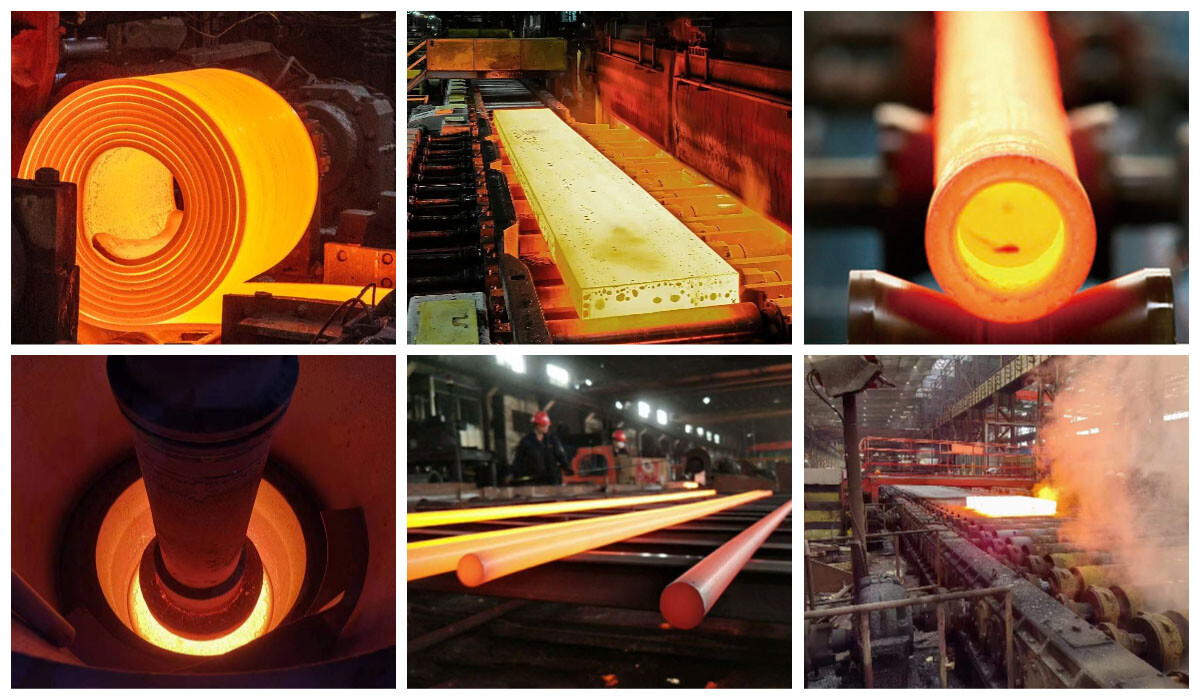

MANUFACTURING PROCESS

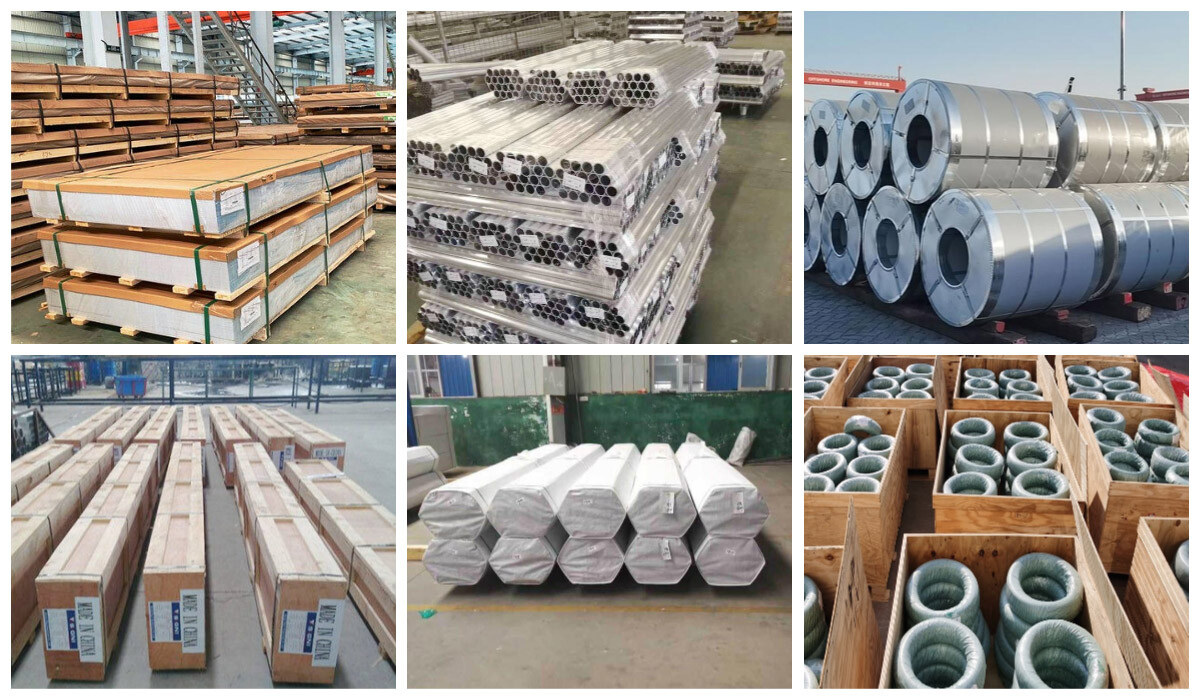

PACKAGING

WHY CHOOSE US

Wuxi Dingyu Xinda Special Steel

Wuxi Dingyu Xinda Special Steel Co., Ltd. is a large sales base for spot supply and production of stainless steel pipes and special materials in China. It mainly deals in various imported and domestic stainless steels, pipes, plates, bars, profiles, pipe fittings and welding materials. The company has a strict and effective quality management system, complies with IS09001: 2008 standard certification, and provides supporting materials for petroleum, chemical, electric power, and shipbuilding industries.

All products of the company comply with the national standard (GB), American standard (ASME, ASTM), Japanese standard (JIS) EN (European standard) GOST (Russian standard), our company holds the ISO9001-2008 quality system certificate issued by TUV Rheinland, Germany and the EU PED/97/23/EC certificate for pressure equipment, API 6A and API 17D certificates issued by API of American Petroleum Institute, and certification of classification societies of eight countries.

LEAVE A MESSAGE

RECOMMENDED PRODUCTS

Please give us a message