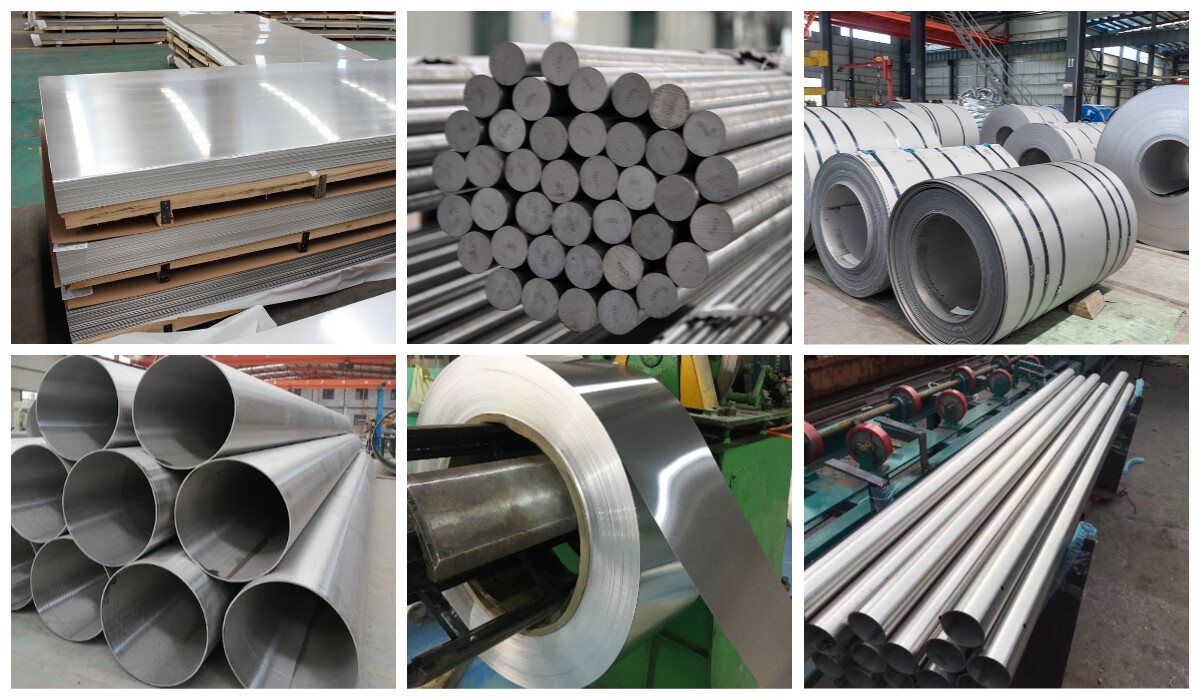

PRODUCTS

PRODUCTS

MESSAGE

2205, 409,410, 410S, 420, 420j1, 420j2, 430, 439, 443,

444,32760,32750,904L,etc

Delivery time:Usually 3-7 days, or upon negotiation

Competitive price and quality from our own factory

Terms of price: EXW, FOB, CFR, CIF

Payment Term:TT,L/C,etc

Certificates: SGS, MTC, ISO9001, CE, SGS

If you have any questions, please feel free to contact us.

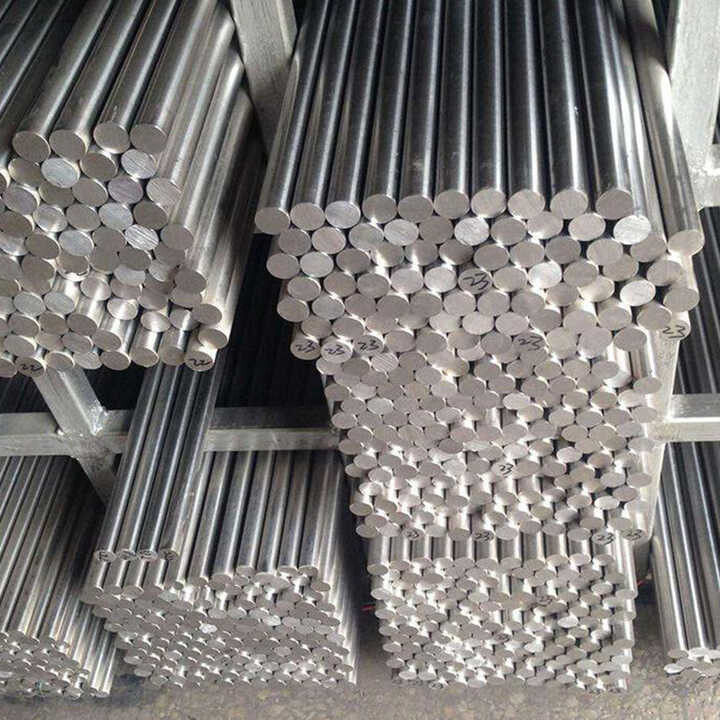

PRODUCT INTRODUCTION

Stainless steel is a steel alloy with increased corrosion resistance compared to carbon/alloy steel.

Common alloying ingredients include chromium (usually at least 11%), nickel, or molybdenum. Alloy content often is on the order of 15-30%.

Common applications for stainless steel include food handling/processing, medical instruments, hardware, appliances, and structural/architectural uses.

Our company specializes in stainless steel products, covering all major categories of stainless steel, and is sold on all continents.

The following are our company's hot stainless steel numbers:

Ferritic stainless steel: 400 series, Crl7, Cr17Mo2Ti, Cr25, Cr25Mo3Ti, Cr28, AISI400, 405, 406MF-2, etc. Commonly used in nitric acid and food factory equipment, gas turbine parts and so on.

Austenitic stainless steel: 201, 304,316 L, 904L, 317LMN, 254SMO, 1Cr18Ni9, 0Cr19Ni9 and other austenitic stainless steel are generally treated with solid solution to obtain single-phase austenitic structure.

Duplex stainless steel: UNS S32304, UNS S31803, DIN1.4582, S32550/2205, S32750/2507,S32760, etc. Compared with austenitic stainless steel, it has higher strength and higher resistance to intergranular corrosion and chloride stress corrosion.

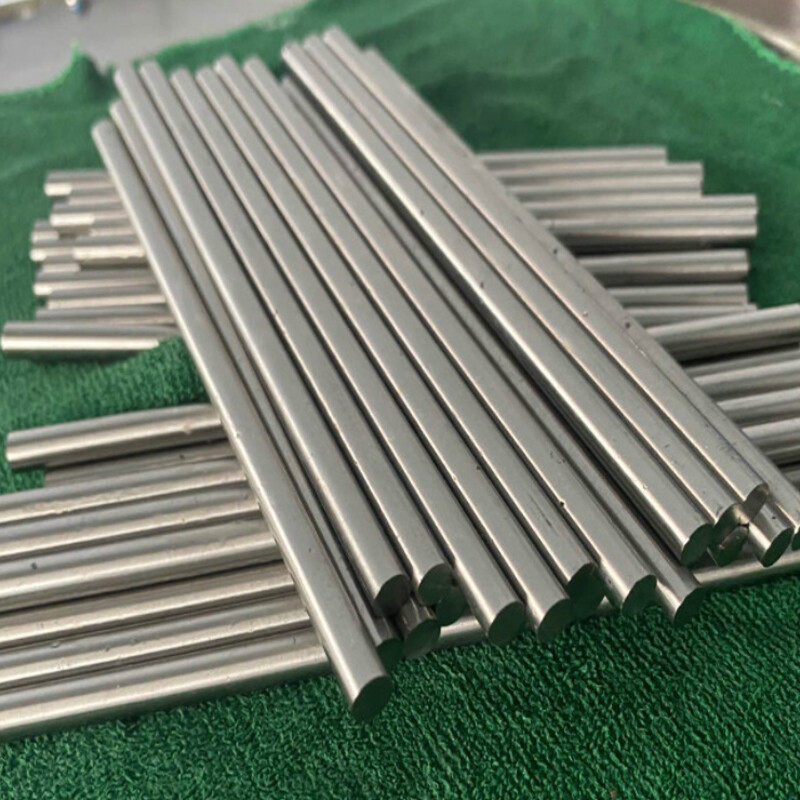

Martensitic stainless steel: 410, 414, 416, 1CR13, 3Cr13, 4Cr13, 9Cr18, etc., used for springs, turbine blades, hydraulic press valves, etc.

High silicon stainless steel: UNS 32615,UNS38815, Zecor-Z,253MA, etc

Urea stainless steel:, 724L, 316LMoD, 06Cr18Ni11Ti, etc., austenitic stainless steel (mod stainless steel) specially developed for urea equipment, it has excellent corrosion resistance and high temperature strength and toughness.

Stainless Steel Description

Stainless Steel Material Properties

Chemical Properties

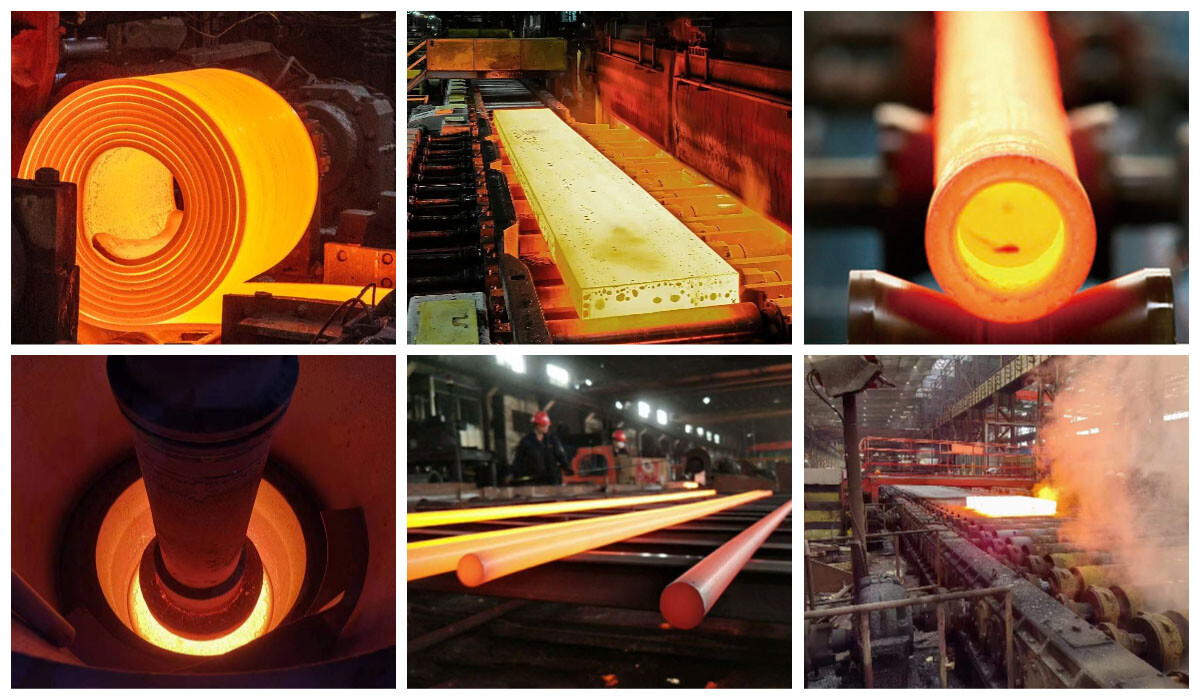

MANUFACTURING PROCESS

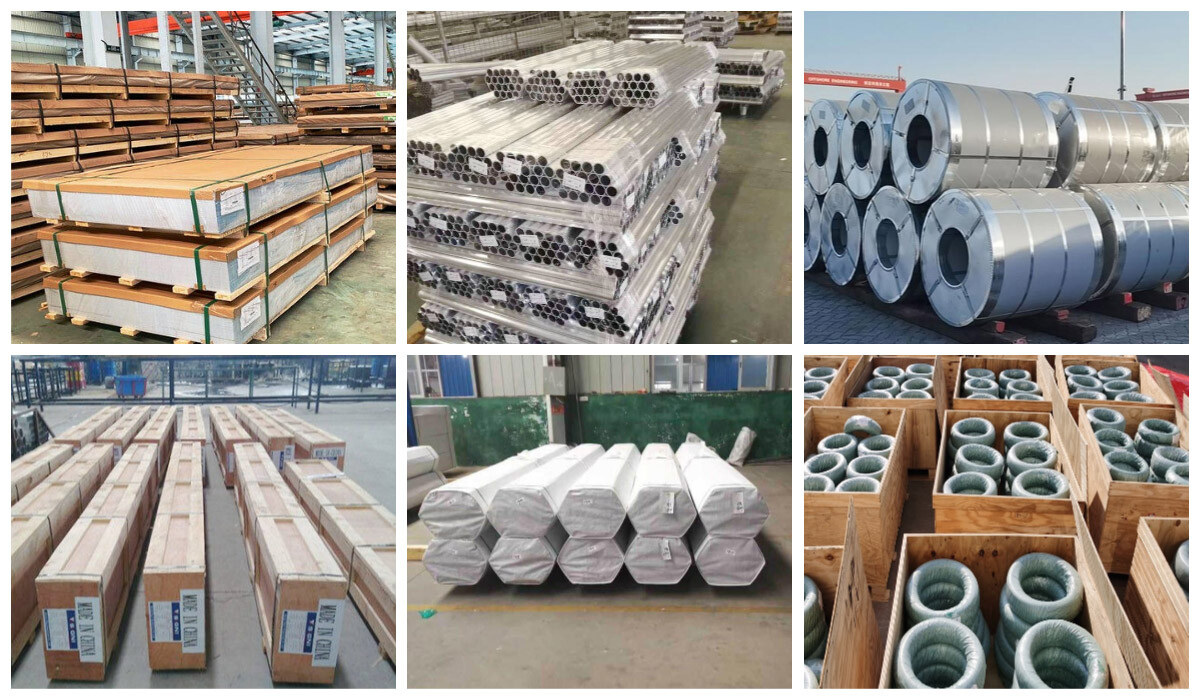

PACKAGING

WHY CHOOSE US

Wuxi Dingyu Xinda Special Steel

Wuxi Dingyu Xinda Special Steel Co., Ltd. is a large sales base for spot supply and production of stainless steel pipes and special materials in China. It mainly deals in various imported and domestic stainless steels, pipes, plates, bars, profiles, pipe fittings and welding materials. The company has a strict and effective quality management system, complies with IS09001: 2008 standard certification, and provides supporting materials for petroleum, chemical, electric power, and shipbuilding industries.

All products of the company comply with the national standard (GB), American standard (ASME, ASTM), Japanese standard (JIS) EN (European standard) GOST (Russian standard), our company holds the ISO9001-2008 quality system certificate issued by TUV Rheinland, Germany and the EU PED/97/23/EC certificate for pressure equipment, API 6A and API 17D certificates issued by API of American Petroleum Institute, and certification of classification societies of eight countries.

LEAVE A MESSAGE

RECOMMENDED PRODUCTS

Please give us a message