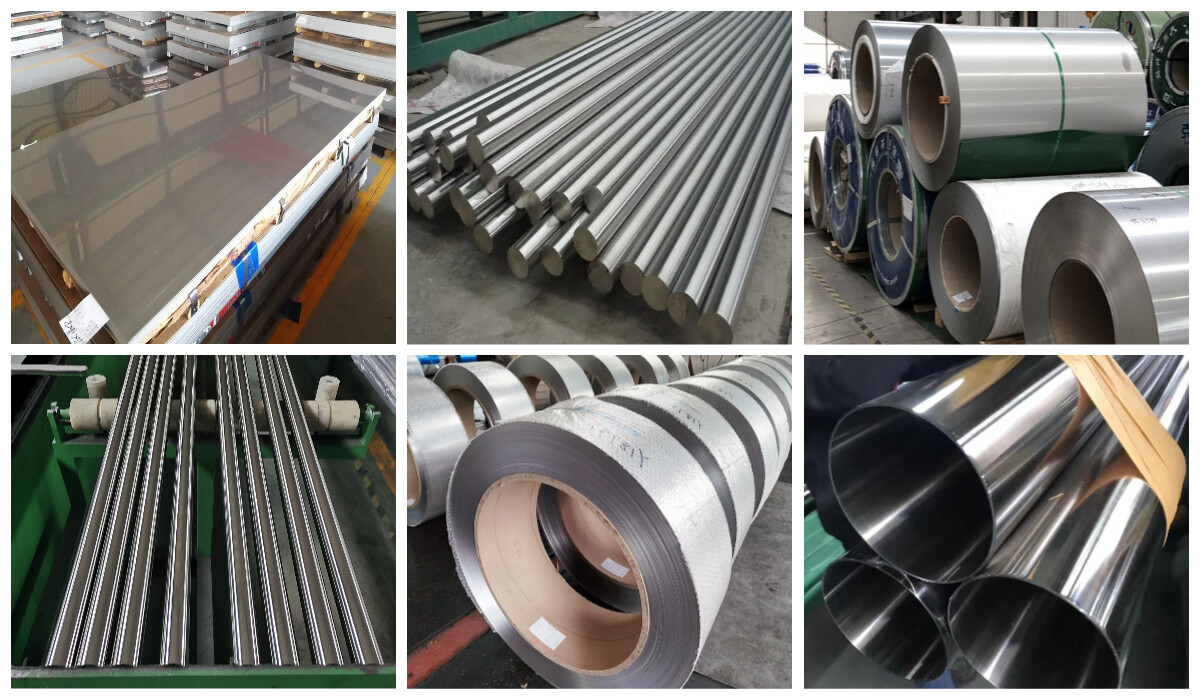

PRODUCTS

PRODUCTS

MESSAGE

ASTM B265 Gr.1,ASTM B265 Gr.2,ASTM B265 Gr.5

Available Standard: ASTM, EN, JIS, GB, etc.

Delivery time:Usually 3-7 days, or upon negotiation

Terms of price: EXW, FOB, CFR, CIF

Payment Term:TT,L/C,etc

Certificates: SGS MTC ISO9001 CE SGS

If you have any questions, please feel free to contact us.

PRODUCT INTRODUCTION

What is Grade 17 Titanium?

Titanium alloys have many excellent properties and can be used in various industries such as consumer electronics, aerospace, medical, marine, military, automotive, and sports equipment. Their main performance is excellent corrosion resistance, very high tensile strength, and durability.

Grade 17 Ti-0.05Pd alloy is very similar to Grade 11. The main difference lies in the varying palladium content. The presence of palladium helps to improve the corrosion resistance of alloys.

Chemical Composition

The chemical composition of grade 17 Ti-0.05Pd alloy is outlined in the following table.

Physical Properties

The physical properties of grade 17 Ti-0.05Pd alloy are tabulated below.

Mechanical Properties

The following table shows mechanical properties of grade 17 Ti-0.05Pd alloy.

Grades Of Titanium Alloys With Properties And Applications

Titanium alloys are available in a wide range of grades, each with its specific properties. The following are some of the most common titanium alloy grades.

Grade 5 Titanium Alloy

Grade 5 is the most common titanium alloy due to its high strength. It is a commonly welding alloy that can function in structural and pressure-containing components. It has high corrosion resistance in both oxidizing and reducing environments.

In addition, it also finds use in the chemical and petroleum industries and the fabrication of offshore drilling platforms. The alloy functions in constructing water treatment facilities, nuclear reactors, and other critical environments requiring a high-strength, low-cost material.

Grade 6 Titanium Alloy

Grade 6 is a commonly welded titanium alloy containing aluminum and tin often used for components exposed to elevated temperatures. In addition to its high-strength properties, the alloy has excellent stability, making it a good choice for airframes and jet engines.

Grade 7 Titanium Alloy

Grade 7 titanium alloy is especially useful for low temperatures and pH applications. This is a result of its extreme corrosion resistance.

Grade 11 Titanium Alloy

Grade 11 is a titanium alloy with good high-temperature strength and high corrosion resistance. The alloy is a raw material for components operating in high temperatures, such as chemical and petroleum processing equipment and manufacturing aircraft engines and airframes. Grade 11 is also used to manufacture turbines, liquid hydrogen storage tanks, and other critical equipment. The alloy is easily fabricated by machining, forging, rolling, and extruding.

Grade 12 Titanium Alloy

It applies to manufacturing aircraft components, such as engine parts, airframes, landing gear, fuel systems, and other critical equipment. The alloy is also used to manufacture cryogenic vessels, heat exchangers, distillation columns, and other equipment operating at high temperatures.

Chemical Composition & Mechanical Properties

Comparison of Titanium vs. Aluminum

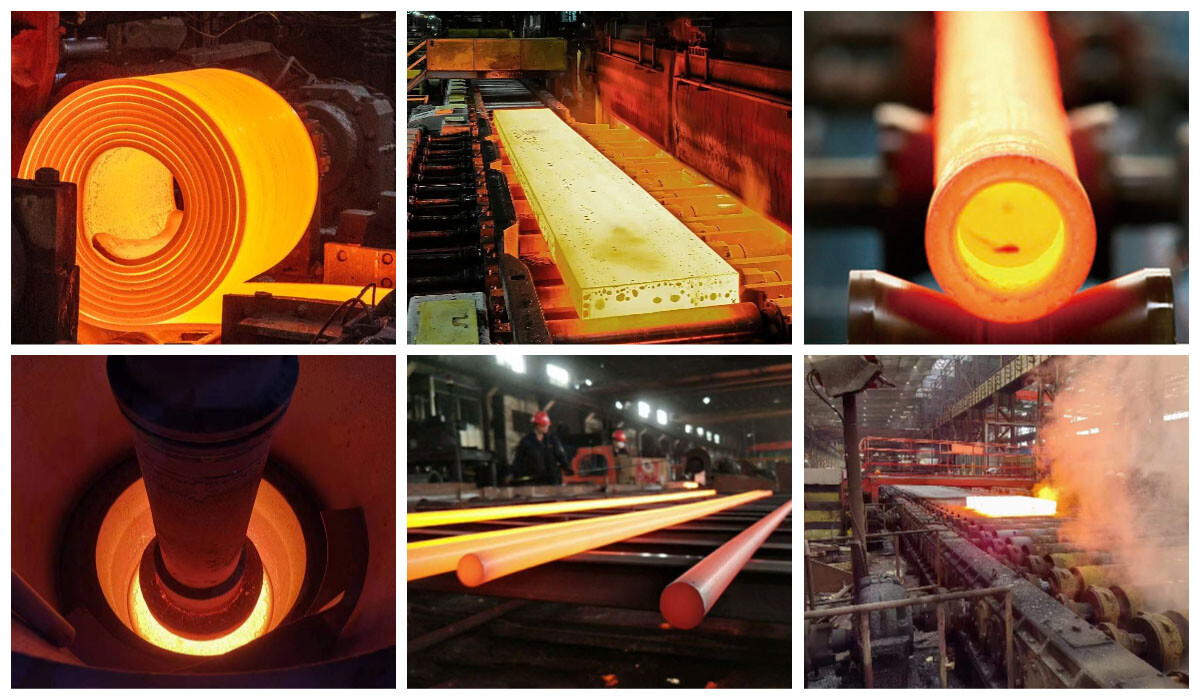

MANUFACTURING PROCESS

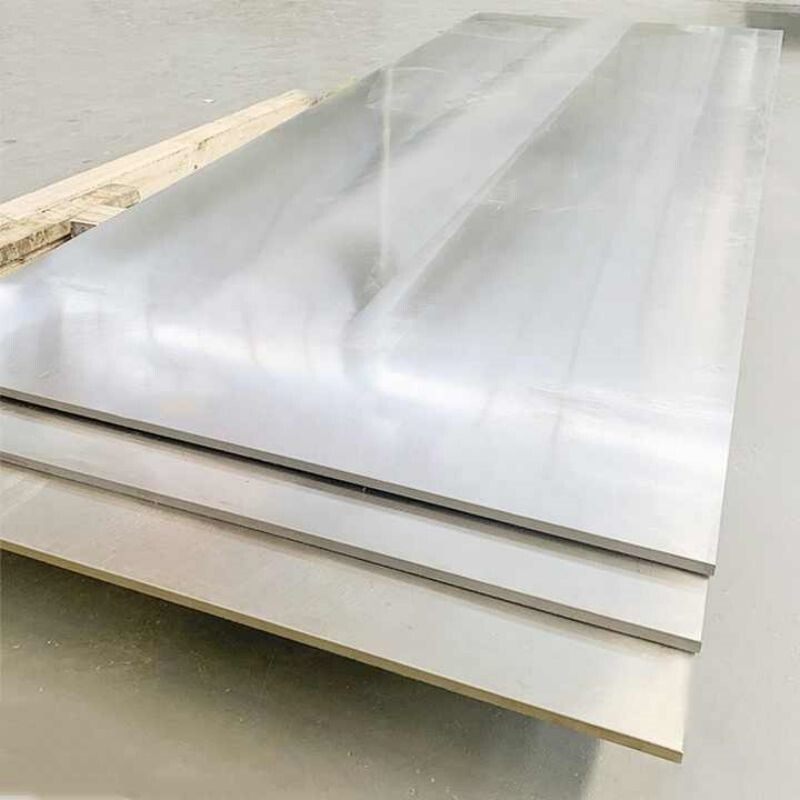

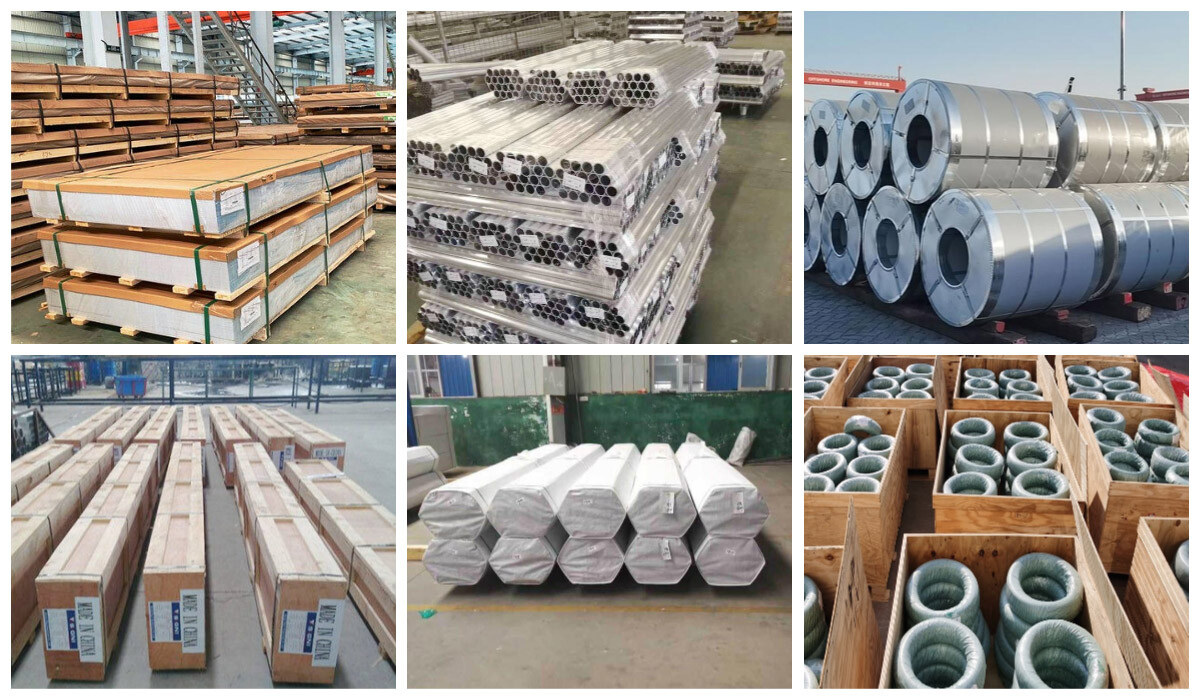

PACKAGING

WHY CHOOSE US

Wuxi Dingyu Xinda Special Steel

Wuxi Dingyu Xinda Special Steel Co., Ltd. is a large sales base for spot supply and production of stainless steel pipes and special materials in China. It mainly deals in various imported and domestic stainless steels, pipes, plates, bars, profiles, pipe fittings and welding materials. The company has a strict and effective quality management system, complies with IS09001: 2008 standard certification, and provides supporting materials for petroleum, chemical, electric power, and shipbuilding industries.

All products of the company comply with the national standard (GB), American standard (ASME, ASTM), Japanese standard (JIS) EN (European standard) GOST (Russian standard), our company holds the ISO9001-2008 quality system certificate issued by TUV Rheinland, Germany and the EU PED/97/23/EC certificate for pressure equipment, API 6A and API 17D certificates issued by API of American Petroleum Institute, and certification of classification societies of eight countries.

LEAVE A MESSAGE

RECOMMENDED PRODUCTS

Please give us a message